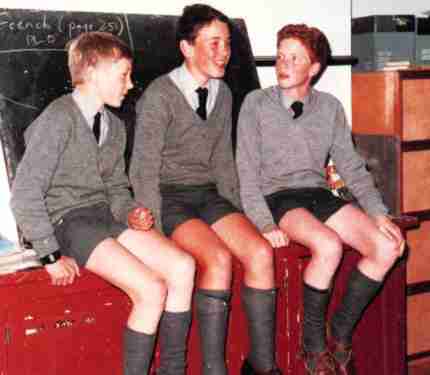

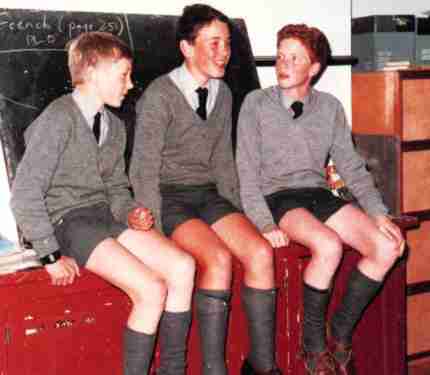

Figure 1.--Terylene grey schools shorts began to appear in the 1950s and by the 1960s had begun to replace the standard gret flannels.

Figure 1.--Terylene grey schools shorts began to appear in the 1950s and by the 1960s had begun to replace the standard gret flannels. |

Synthetic fibers were invented in 1884 from cellulose by a Frenchman

named Hilarie de Chardonnet. Rayon, the generic term for regenerated cellulose fibers (derived from trees, woody plants, and cotton). Production in quantity did not begin, however, until the invention of the vicose

process patented in England during 1892. The first product was marketed as artifical silk. The first chemically created fiber was nylon which was invented in 1938 by Dupont. It did not become available for commercial use until after the end of World War II in 1945. A host of other new fibers followed soon nylon.

Most synthetic fibers used for clothing are polyester, which means a fiber composed of polymers (molecular structures) manufactured from petro-chemicals. These polymers are processed into filiments of polyester, often textured to resemble some material we are familiar with and made into yarn. Finally the yarn is manufactured into polyester fabric. The main trade names in America are Dacron, Fortrel, Trevira, and Zefran. In Britain one of the main trade names was Terylene. The fabric can be either 100 percent polyester or blended with natural or

other man-made fibers to produce percentage-blended cloth. Fiber content labels on clothing reveal by law the nature and percentage of these blends.

The primary reason for using polyester fabric for clothing is low cost. Polyester costs only about 75 percent of the cost of manufacturing natural

fibers. It accounts for a very sizeable proportion of world cloth manufacture. It has, however, an image problem with the much joked about polyester

leisure suit.

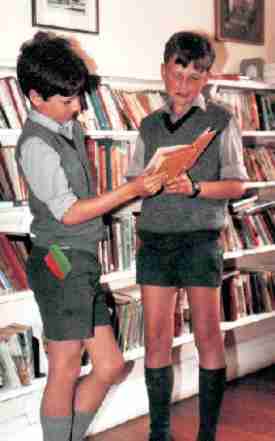

Figure 2.--The new shorter Continental style of short pants was common in the 1970s and early 1980s. |

Polyester and polyester belends have several other advantages beyond cost in the manufacture of children's clothes. Polyester is much easier to maintain that flannel and other woolen garments. They can be machine

washed and dried, often without ironing. Garments that require dry cleaning, especially for children, can entail considerable cost. This is especially

true for boys' clothes which will invariably require constant washing.

I am not sure of the blend use for Terylene shorts. Some may have been 100 percent Terylene, but the better quality ones were mixed blends including

wool and perhaps some cotton. Perhaps our English contributors can provide some information on this.

In making woolen garments,like flannel, the natural characteristics of

the fiber--its curliness and felting power--are developed by the manufacturing

processes and produces a soft cloth with a nap and with the fibers so

matted together that the weave is but lightly visible. In worsted

manufacture the aim is to produce a smooth, wiry yarn, more like that of

the other textile fibers. To this end the fibers are straightened out,

twisted hard, and the shorter projecting ones which would form a nap combed

out. This produces a cloth in which the weave is evident and a great variety

of design in weaving is possible. In making woolen yarn the wool is simply

carded and loosely spun.

Terylene shorts continued many of the sylistic characteristics of

flannel shorts with a few differences. Almost all Terylene shorts were

grey. A few schools had blue shorts--but only a handful in England.

They were mostly made without back pockets. The major difference was

that most

of the Terylene shorts were made with zippers frather than the traditional

buttons. The other major difference was at the time Terylene became

increasingly popular, the shorter Continental style of short pants was

becoming popular in England. Thus the Terylene shorts were

mostlty made in the shorter Continental style.

Synthetic fibers like Terylene began to become available after World

War II. Most schools at the time had uniforms with grey flannel

short pants. The conservative nature of the schools, especially the

private schools, caused the schools to continue insisting on flannel

shorts during the 1940s and 50s.

Gradually schools began to turn to Terylene worsted shorts in the 1960s.

The easy care characteristics of sythetic fibers finally one the day.

Mums and matron could easily put Terylene shorts through the washing machine.

No ironing was required. Quite a savings in time and money over flannel

which had to be dry cleaned. One feature which may have even won over

conservative school masters was the sharp crease Terylene shorts held,

much different than the baggy look of flannels. All in all not only were

the Terylene shorts less expensive and easier to care for, but they

gave the boys a much smarter look. This was an important consideration

to English headmasters and school masters who gave considerable importance

to the school uniform.

Navigate the Historic Boys' Clothing Web Site:

[Return to the Main school uniform garment page]

[Introduction]

[Chronologies]

[Style Index]

[Biographies]

[Bibliographies]

[Contributions]

[Frequently Asked Questions]

[Links]

[Boys' Clothing Home]