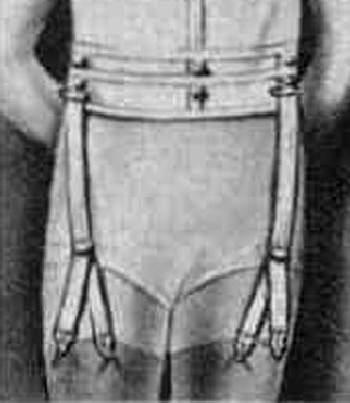

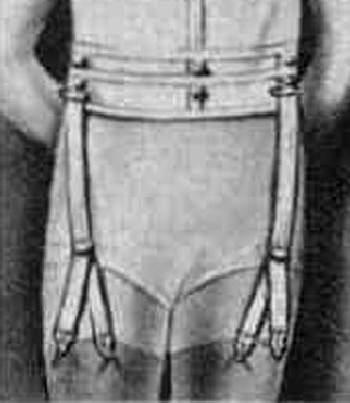

Stocking Supporters: Sadety Pin Attachmentment Devices

Figure 1.--This Wards underwaist (Spring-Summer 1940 catalog) clearly shows the metal pin tubes through which safety-pin-top supporters can be fastened. The pin tubes are located on the sides of the waist just underneath the buttons

for attaching short trousers. The pin-on supporters are attached but can be removed.

|

|

After suspended strap elasric garters began to be manufactured with safety pins for attachment, several devices were developed for attaching the saftey pins on to the dufferent support garments. These provided for the easy and secure attachment. The attachment devices commonly included attaching metal tubes, eyelets, and tape loops. They were incorporated on both underwaists/waist suits and waist union suits. Garter waists came with the elastic garters already attached.

The technology that seems to have been the most popular for attaching garters to support devices was safety pin tubes. They became almost universal. The Hunkins pin tube was a hollow cylinder sewn or fastened to a strong cloth tab through which the safety pin could be secured. As one ad explains, "Slip the pin at the top of the hose supporter through the pin tube. No wearing or tearing of the garment by the hose supporter. The pin can't bend, sag or become unfastened. The supporter keeps its proper position and cannot pull at one end of the pin" Pin tubes were later made of nickle or some other non-rusting metal to prevent rust stains on underwear .William S. Hunkins invented the pin-tube adopted by the Minneapolis Knit Works and other manufscturewrs. He lived in Hollywood, California, during the early decades of the 20th century. We see his inventionalready in use as early as 1904--the waist. Refinements of the device were still being patented by Hunkins in 1921 and 1929. The most popular waist of all and the most extensively advertised became that of the Stein Company in Chicago (manufacturers of Hickory Waists and Garters). These ads refer to the "patent pin tube" but don't mention the name of the inventor, William S. Hunkins. The Hunkins pin tube became so familiar and so much used that eventually manufacturers no longer bother to specify that it had been invented by Hunkins. But Hunkins is important because his device was so widely adopted and used. The 1940 Wards ad here is a good example (figure 1).

The use of eyelets was another method of attaching the garters. Some waists and waist union suits were made with eyeleted garter tabs to hold the safety pin of the hose supporter. A little tape tab was sewn onto the gartment and made of flexible but sturdy material. The tab had two spaced holes or eyelets piercing the tab through which the garter safety pin passed to hold the hose supporter firmly in place. Usually the holes were made with metal surrounds or

lining so that the safety pin would not tear the fabric of the tab. These eyelets were made like the eyelets in lace-up shoes through which the shoe strings of modern shoes are passed. Similar eyelets were used in the lacing up of women's corsets. If the two eyelet holes were spaced properly on each of the two tabs, the garter pin could not twist

and turn or pull the waist out of shape. We are not sure when they first appeared. They became fairly prevalent during the 1910s and 1920s. Eaton's in Canada advertised a boy's waist in 1918-19 that featured tabs with two eyelets to hold the safety pins of the supporters. Eyelet garter tabs continued to be used on many waists even after pin tunses became prevalent. One of the models in the illustration on the main underwaist page shows a waist with eyelet tabs in 1929.

Tape loops were another method for attaching the garters to the support garment. This is the simplest of the three devices. Manufacturers simply sewed a heavy loop made of strong tape onto the sides of waists and waist union suits to hold the garters in place. The heavy loops were strong enough to stand the strain and wear of attaching saferty pins.

The safety pin of the supporter was simply opened, slipped through the loop, and then closed again. The loops were almost as wide as the length of the pin so that the hose supporter could not slip and slide around once it was attached. The loop-style garter tab was of course attached to a supporting shoulder tape with which the waist was reinforced, so that the pull of the garter would not pull the waist out of shape or tear the fabric of the waist. We are not sure when these loops first appeared or what company introduced them. Sears in 1927 advertised waist union suits for boys with heavy tape loops at the sides through which the supporter safety pins could be fastened Tape loops were touted by the E-Z Waist Company as avoiding the problem of rusting or being flattened by wringers in washing machines. E-Z Waists made much of the tape loop, arguing that it was better than a metal tube because it wouldn't rust when laundered or get bent out of shape in the wringer of old-style washing machines.

HBC

Navigate the Boys' Historical Clothing Web Site:

[Return to the Main attaching suspended strap garters page]

[Return to the Main supporting long stockings page]

[Return to the Main underwaist page]

[Return to the Main waist union suit page]

[Return to the Main underwear garment page]

[Introduction]

[Activities]

[Biographies]

[Chronology]

[Clothing styles]

[Countries]

[Bibliographies]

[Contributions]

[FAQs]

[Glossaries]

[Registration]

[Tools]

[Boys' Clothing Home]

Created: 3:38 AM 1/18/2010

Last updated: 3:38 AM 1/18/2010